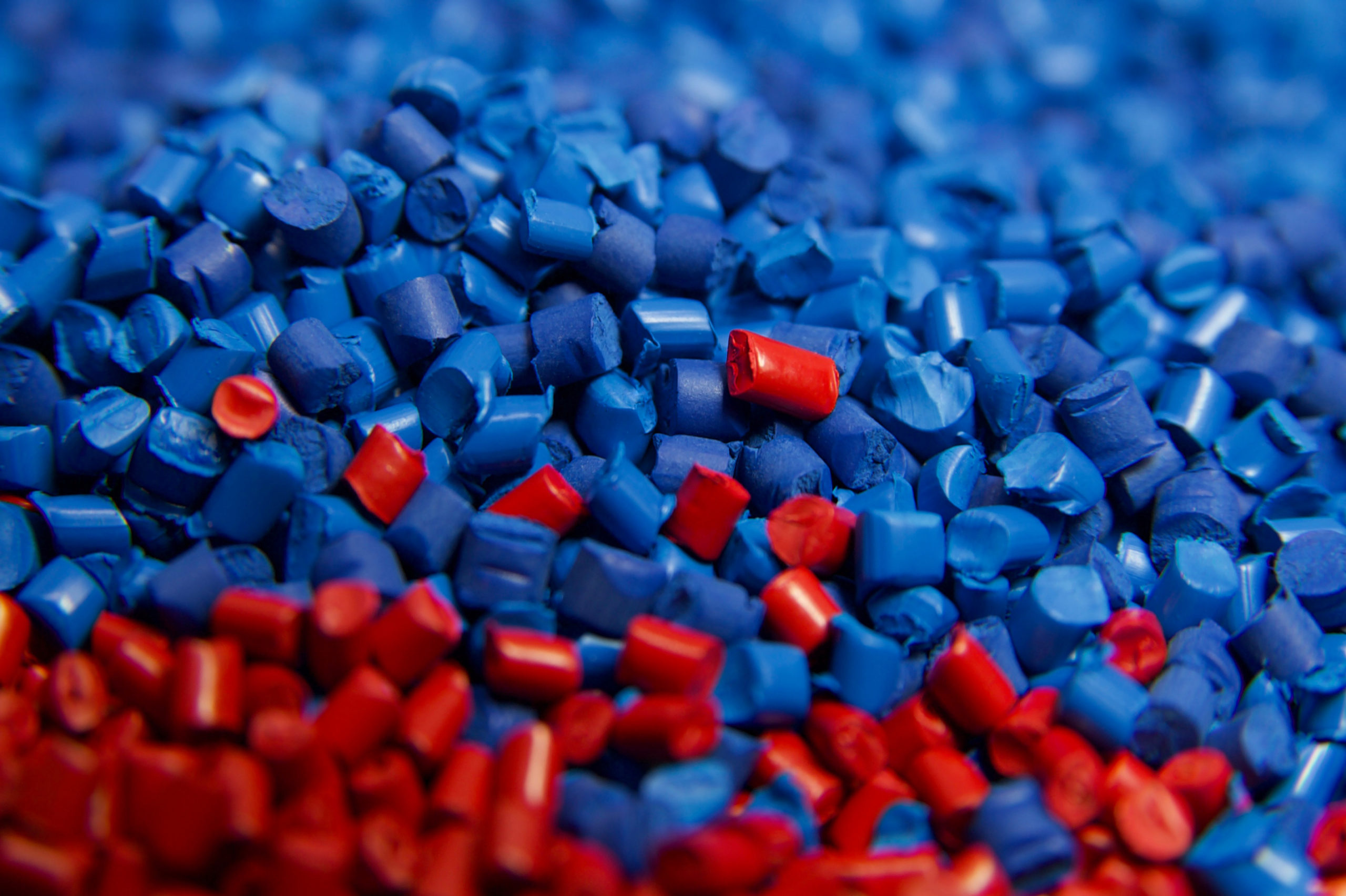

IPG, also known as “nurdles”, are small plastic beads used as a raw material in the manufacture of various plastic products. However, their dispersion in the environment can have serious ecological consequences. This is why IPG loss prevention audits have become essential to ensure sustainable, environmentally-friendly plastic production.

Understanding the risks of IPG losses

Losses of IPG can occur at several stages in the supply chain, from production through storage and transport to end use. These small plastic beads have the ability to disperse easily in the environment, including waterways, soils and marine ecosystems. Once in the environment, granules can have worrying effects on flora and fauna, via ingestion or very slow decomposition for example.

Importance of the IPG loss prevention audit

IPG loss prevention audits are systematic assessments of the practices and processes implemented by companies in the plastics industry to prevent granules leaking into the environment. These audits aim to identify weak points in the supply chain and recommend corrective measures to minimize the risk of IPG dispersion.

Recommended preventive measures

Several preventive measures can be implemented to reduce IPG losses:

- Inventory management: Implement strict inventory management procedures to minimize the risk of accidental IPG spills during storage and handling.

- Staff training: Educate and train staff in good IPG handling practices to reduce the risk of accidental loss during day-to-day operations.

- Protective equipment: Provide workers with adequate protective equipment, such as drip pans and containment barriers, to prevent IPG spills during loading and unloading.

- Monitoring and follow-up: Set up a monitoring and follow-up system to detect IPG leaks early and take immediate corrective action to limit their spread.

IPG loss prevention audits have several advantages:

- Reducing environmental risks and impacts on flora and fauna.

- Improved compliance with environmental regulations.

- Become an environmentally responsible player.

- Reduced costs linked to raw material losses and cleaning operations.

Preventing losses of industrial plastic pellets is a responsibility shared by the entire plastics industry. IPM loss prevention audits provide an essential framework for assessing and improving pellet management practices, thereby reducing environmental risks and strengthening the sustainability of the plastics industry. By investing in effective preventive measures and integrating responsible IPM management into their operational strategies, companies like AMP and POLYMIX can play an active role in preserving the environment and promoting a sustainable economy within the plastics industry.

Leave a Reply